They trust Matam:

Our top Products

Matam develops a wide range of very competitive products covering all typical problems and resolving thus all wearing problems such as abrasion, corrosion, cavitations and impact.

CRUSHER

SPARE PARTS

Spare parts for Gyratory cruchers, Cone cruchers, Electric shovels, Draglines, Hydraulic shovels, Screens

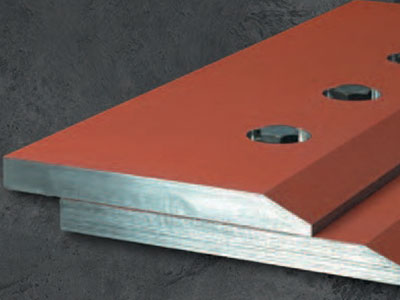

ABRASION RESISTANT PRODUCTS

Abrasion resistant steel plates produced by ThyssenKrupp Germany. Ideal for chutes, bins, cutting edges,…

DIRT WHACKER

BELT CONVEYOR CLEANER

We manufacture, stock and commercialise worldwide the wonderful belt scrapers “DIRT WHACKER®”

We are problem solvers

We can help you whatever problem you are facing: crushing problems, abrasion, cavitation and impact in mines, quarries, cement factories, steelworks or other industries…

Any mining problem to solve?

A TRUSTED PARTNER

Matam is a trusted partner in the mining industry, renowned for innovative solutions that effectively address abrasion challenges. With a proven track record of reliability, our products contribute to cost savings and minimized downtime. Guided by a client-centric approach and expert support, Matam is a valued partner for mining professionals.

info@matam.be

Phone

Phone : +32 (0)2 354 67 34

Address

Zoning Artisanal de Waterloo

Av. des Pâquerettes, 55 - Bte 42

1410 Waterloo

Belgium

Need spare parts?

Premium replacement parts for major brands: Sandvik, Metso, Allis-Chalmers, Symons, Nordberg, Raptor, XAR and many more…